Our 4-step production

|

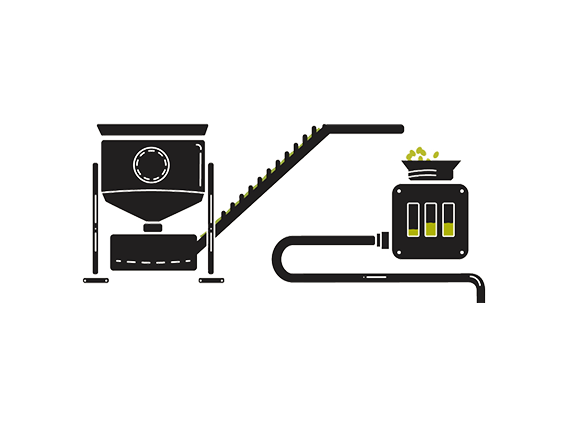

1. Harvest The period of harvest plays a severe role in producing good quality olive oil. Harvest usually takes place around November or December making olive oil distinct for its dark green color and its outstanding fresh flavor. After the harvest of olives are placed into wooden boxes with holes, preventing high temperatures and reassuring air flows into the boxes. The sooner olives are transported to Oil Mills the better (usually within 24 hours). |

|

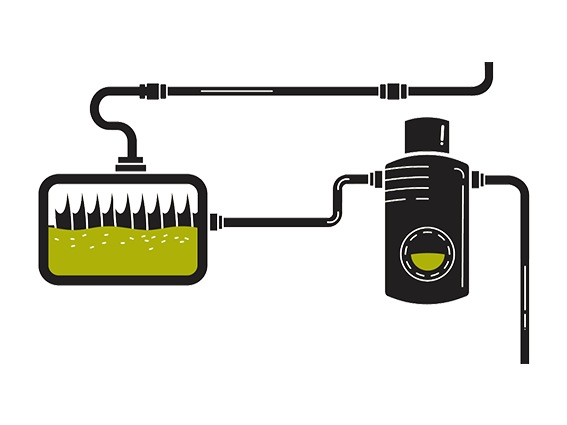

| 2. Cold pressing When Oil Mills receive the olives, the first step it takes towards olives production is to clean them by separating them from any leaves, mud, branches or other leftovers accumulated during harvest. The second step concerns pressing the olive with its very core, creating a thick paste. The aim of pressing is that its layer is melted so the oil can be more easily extracted – imitating our Minoan ancestors who used to do the same procedure on millstones. The paste mixture is moulded for 20 to 45 minutes in order that oil drops that are dispersed into the paste form bigger drops separating them from all the other solid or fluid ingredients. It’s an indispensable step into producing high quality oil. After moulding, cold water - 27oC - is added into the paste and moulding continues. The mixing goes on for an hour slowly surfacing oil due to the cold water. This is why we call it cold pressing. |

|

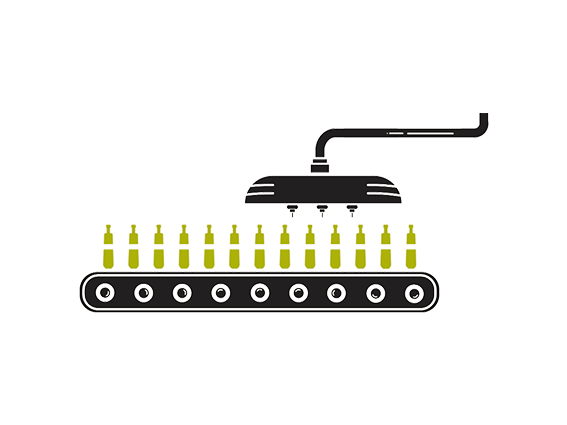

| 3. Standardization During its transportation from Oil Mills to Standardization factory, oil is kept into specially designed tanks. Only the carefully selected oil is standardized. Our production is responsible for giving you into diligently and uniquely designed bottles our best oil with vivid green color and intense flavor. Only the best wrapping paper is chosen for our products. |

|

4. Storage Our storage differs from production areas. It is manufactured to maintain stability in temperature and light. Our product is mindfully stored under the perfect roof. The tanks are air-tight and armed with assistive filling an emptying systems touching the bottom as well as drainage pipes and some for sample taking. |